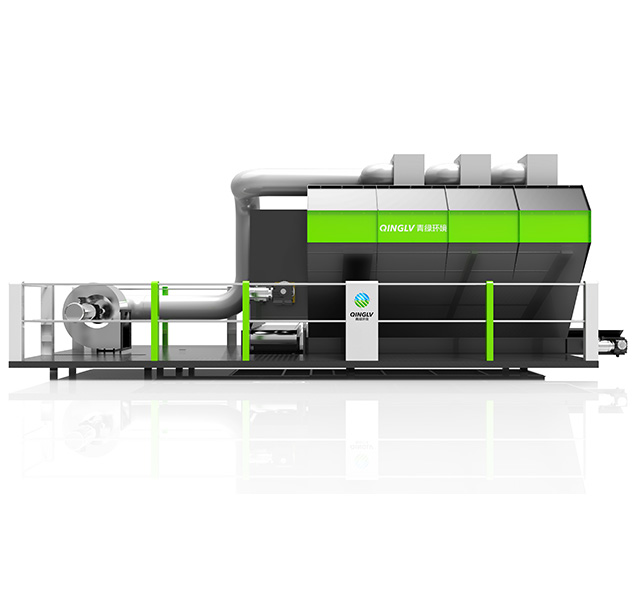

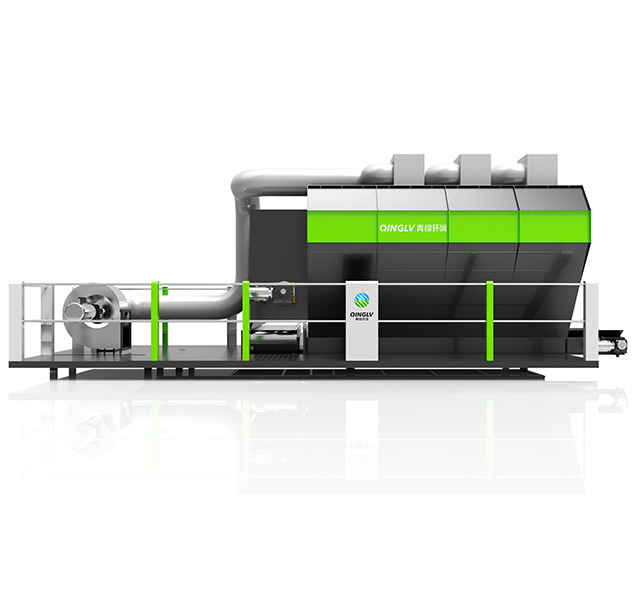

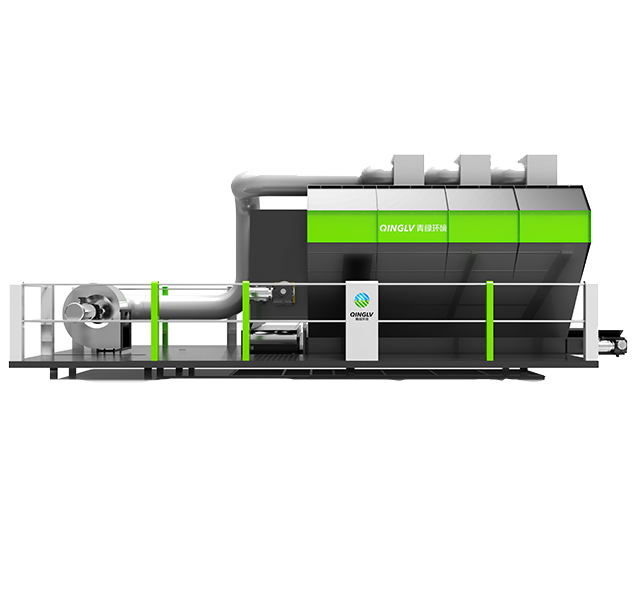

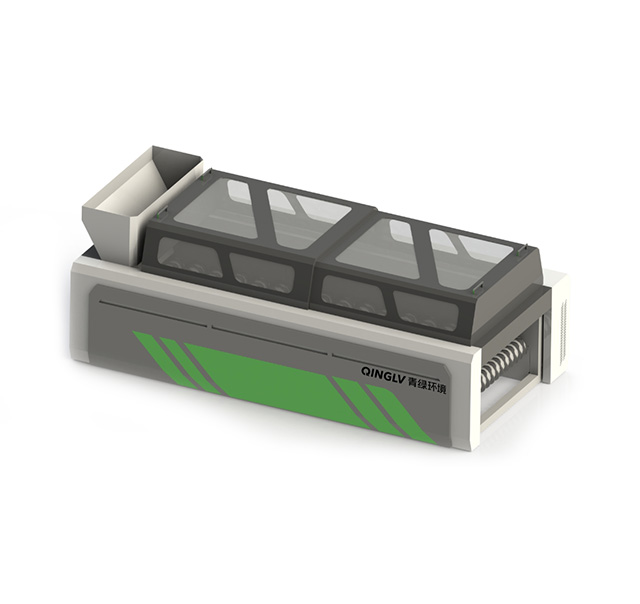

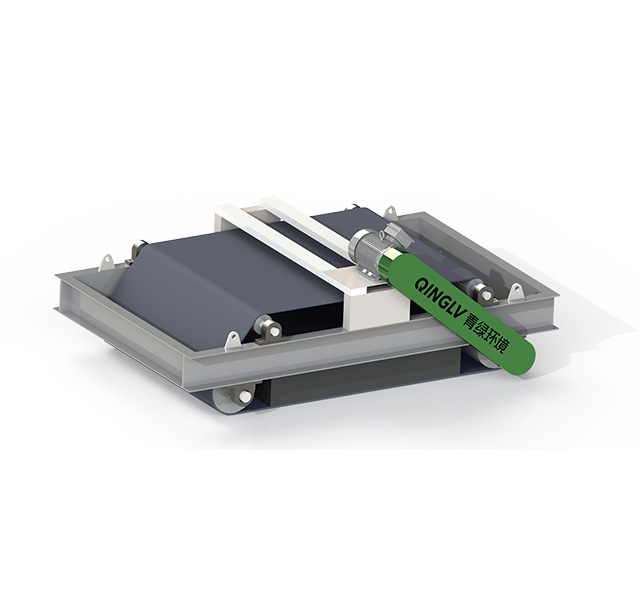

Wind Shifter

The wind shifter mainly consists of a circulating fan, separation drum unit, conveyor, diffusion chamber, and dust collector. This equipment uses the principles of aerodynamics, with controllable airflow as the sorting medium, to air-select the materials according to their density and particle size. The airflow can carry lighter materials (such as paper scraps, feathers, plastic bags, dead leaves, etc.) upwards or to a farther place horizontally, while heavier materials naturally fall or are thrown horizontally for a closer distance due to inertia.

Qinglv's wind shifter has a simple structure, which is easy to maintain.Equipment adjustment is flexible and convenient. Its negative pressure suction environment providing better separation effects.

Advantages

Application Areas

Technical data

Qinglv-800 Qinglv-1200 Qinglv-1400 Qinglv-1600

Cases

-

Malaysia Kuala Lumpur Paper Mill Waste Project

Lower 30 %Investment costFaster

30 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 20 %Recycling benefits

20 %Recycling benefits -

Guangdong Dongguan Industrial Solid Waste Project

Lower 40 %Investment costFaster

40 %Investment costFaster 40 %Payback cycleHigher

40 %Payback cycleHigher 10 %Recycling benefits

10 %Recycling benefits -

Shaanxi Yulin Municipal Solid Waste Sorting Project

Lower 40 %Investment costFaster

40 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 15 %Recycling benefits

15 %Recycling benefits