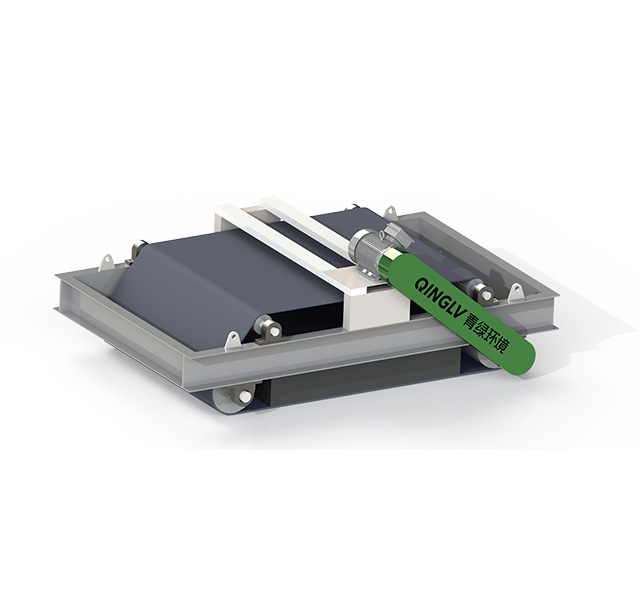

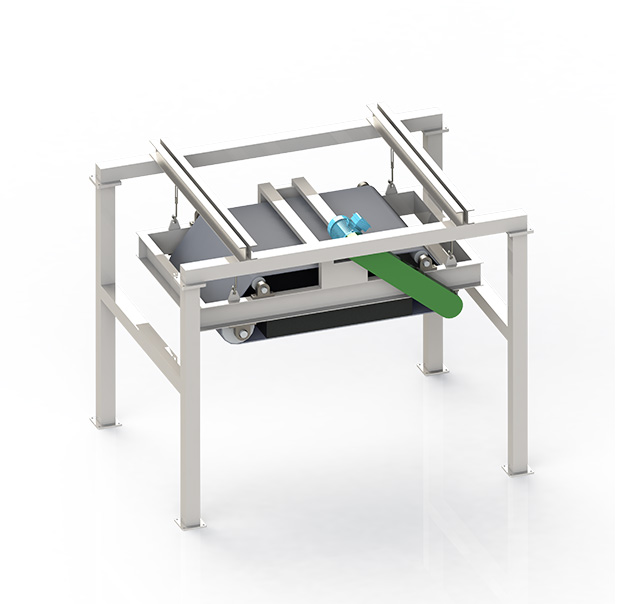

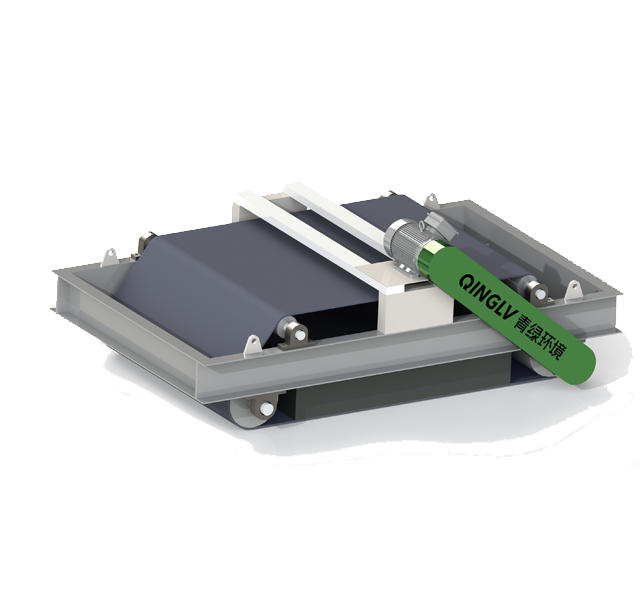

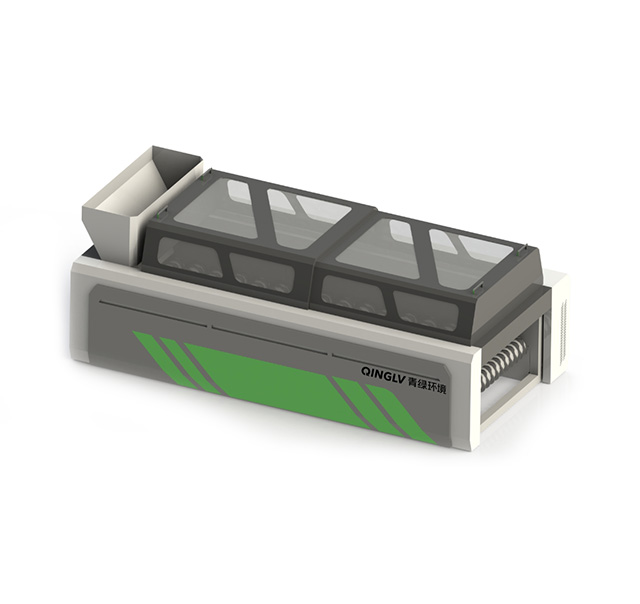

Magnetic Separator

The magnetic separator is used to automatically separate magnetic materials from mixed waste, thereby purifying organic waste and recovering scrap metal.

Qinglv's magnetic separator utilizes high-quality ferrite materials, with a magnetic field strength that can reach up to 1650mT. It is characterized by its large processing capacity and resistance to demagnetization.

Advantages

Application Areas

Technical data

RCYD(C)-5 RCYD(C)-6 RCYD(C)-8 RCYD(C)-10 RCYD(C)-12 RCYD(C)-16 RCYD(C)-20

Cases

-

Guangdong Dongguan Paper Mill Waste Project

Lower 30 %Investment costFaster

30 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 20 %Recycling benefits

20 %Recycling benefits -

Malaysia Kuala Lumpur Paper Mill Waste Project

Lower 30 %Investment costFaster

30 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 20 %Recycling benefits

20 %Recycling benefits -

Yunnan Kunming Landfill Waste Project

Lower 30 %Investment costHigher

30 %Investment costHigher 10 %Recycling benefits

10 %Recycling benefits -

Shanghai Recyclable Waste Project

Lower 30 %nvestment costFaster

30 %nvestment costFaster 20 %Payback cycleHigher

20 %Payback cycleHigher 15 %Recycling benefits

15 %Recycling benefits -

Guangzhou Construction and Demolition Waste Recycling Project

Lower 40 %Investment costFaster

40 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 15 %Recycling benefits

15 %Recycling benefits