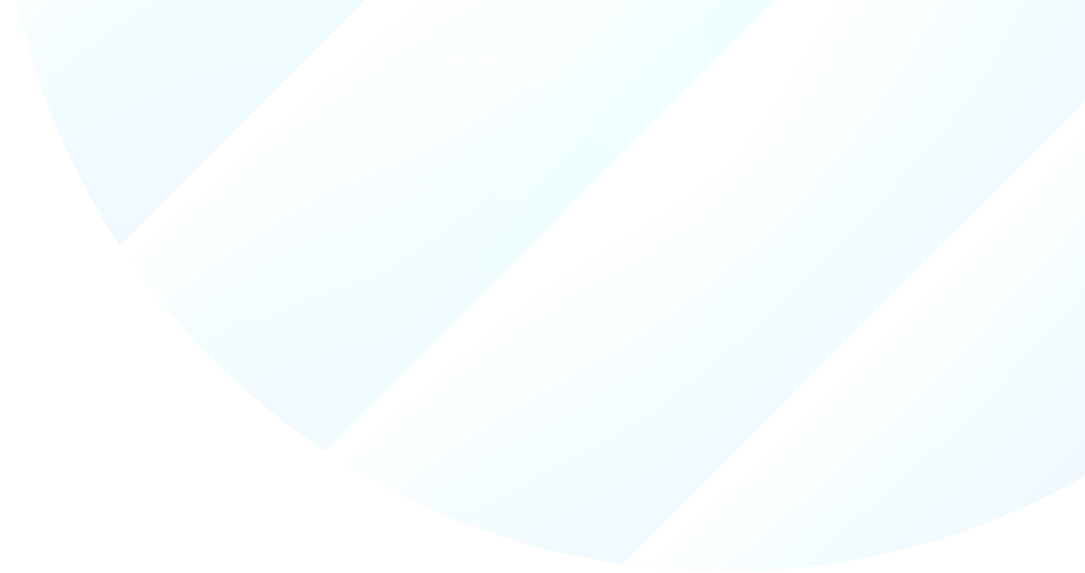

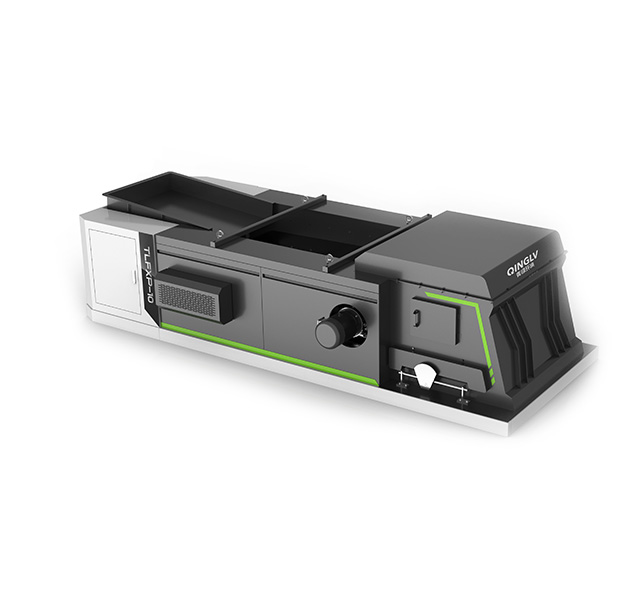

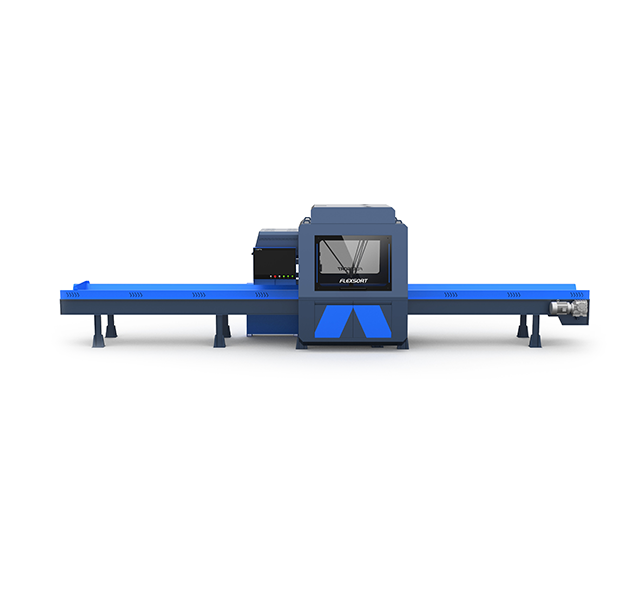

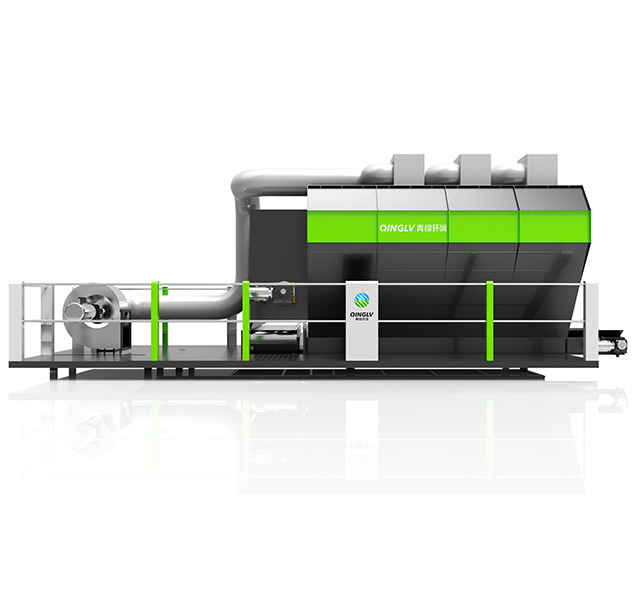

Eddy Current Separator

The Eddy Current Separator is utilized for the efficient sorting of non-ferrous non-magneticmetals. Common solid waste including msw, industrial solid waste, slag waste, electronic waste, and scrapped car, often contains non-ferrous metals such as copper and aluminum. After crushing these materials, the eddy current separator can automatically separate and sorting the non-ferrous metals, significantly increasing the added value of the products.

Qinglv's Eddy Current Separator features an ultra-high-frequency rotor and high-end magnetic materials, resulting in higher sorting purity. Its patented balanced design ensures more stable operation, while advanced anti-corrosion and wear-resistant technologies enable the equipment to withstand harsh environments, including high temperatures and acidic conditions. Additionally, various models can be customized to meet the specific needs of customers.

Advantages

Application Areas

Technical data

Qinglv-400 Qinglv-600 Qinglv-800 Qinglv-1000 Qinglv-1200

Cases

-

Malaysia Kuala Lumpur Paper Mill Waste Project

Lower 30 %Investment costFaster

30 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 20 %Recycling benefits

20 %Recycling benefits -

Guangdong Dongguan Industrial Solid Waste Project

Lower 40 %Investment costFaster

40 %Investment costFaster 40 %Payback cycleHigher

40 %Payback cycleHigher 10 %Recycling benefits

10 %Recycling benefits -

Shaanxi Yulin Municipal Solid Waste Sorting Project

Lower 40 %Investment costFaster

40 %Investment costFaster 30 %Payback cycleHigher

30 %Payback cycleHigher 15 %Recycling benefits

15 %Recycling benefits